When planning a construction or solar installation project, one of the most important decisions involves choosing the right type of foundation. Two common options are ground screws and traditional concrete foundations. While both provide structural support, they differ significantly in terms of installation time, materials, labor, and overall cost. This post explores the cost differences to help you make an informed decision.

Ground Screws:

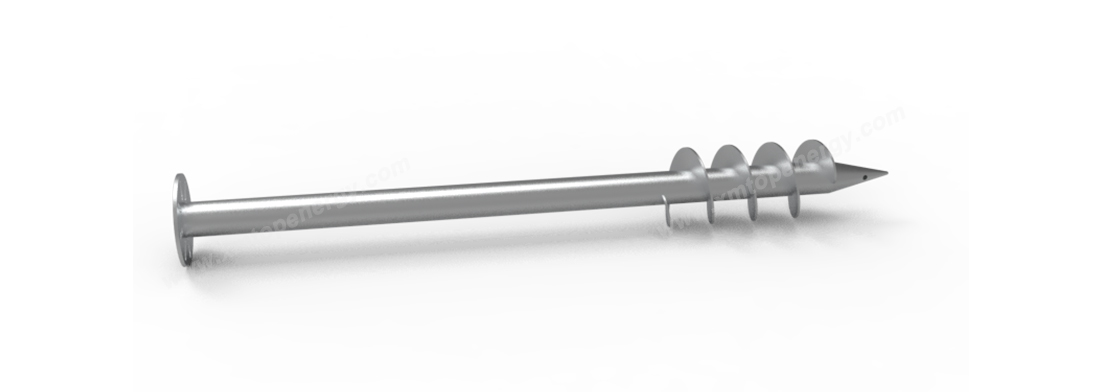

Ground screw piles are prefabricated galvanized steel elements. Their cost per unit can be higher than raw concrete per square foot. However, because they are ready-made and don’t require formwork or curing, you often save in other areas.

Traditional Foundations:

These require concrete, rebar, formwork, and sometimes gravel or sand layers. The material costs themselves may appear cheaper at first glance, but added requirements like mixing, transportation, and curing time contribute to higher total costs.

Verdict: Ground screws have higher upfront material costs, but they reduce the need for supporting materials and logistics.

Ground Screws:

Quick to install—most systems can be screwed into the ground within minutes using handheld or machine-mounted drivers. No drying or settling time is required, and weather delays are minimized.

Traditional Foundations:

Require excavation, setting forms, pouring concrete, and waiting for curing (often several days). This process is labor-intensive and can be affected by weather conditions.

Verdict: Ground screws offer significant labor and time savings—often reducing installation time by 50–70%.

Ground Screws:

Require minimal excavation. They can be installed on sloped or uneven terrain with minimal ground disturbance, reducing the need for grading and preparation.

Traditional Foundations:

Require a flat and stable base. Additional costs are often incurred in leveling the ground or building retaining structures.

Verdict: Earth screws are more cost-efficient in challenging terrain due to minimal prep work.

Ground Screws:

Made from corrosion-resistant materials and designed for long-term use. In many cases, they can be reused if the structure is relocated.

Traditional Foundations:

Generally durable but can crack or degrade over time, especially in areas with freeze-thaw cycles or poor drainage. Repair can be costly.

Verdict: Both offer long-term durability, but ground screws provide added value with flexibility and reusability.

Ground Screws:

Lower environmental impact due to less soil disruption and the potential to avoid excavation permits. This can reduce compliance costs and timeline risks.

Traditional Foundations:

Heavier environmental footprint due to excavation and concrete use. Permit processes may be more complex and time-consuming.

Verdict: Ground screws often lead to indirect cost savings through easier permitting and a lower environmental impact.

|

Cost Factor |

Ground Screws |

Traditional Foundations |

|

Material Costs |

Higher/unit |

Lower/unit |

|

Labor & Time |

Lower |

Higher |

|

Site Preparation |

Minimal |

Extensive |

|

Maintenance/Flexibility |

High (reusable) |

Moderate (permanent) |

|

Environmental Costs |

Lower |

Higher |

While ground screw anchors may appear more expensive in terms of unit price, they frequently result in overall lower project costs due to faster installation, reduced labor, and minimized site preparation. For solar installations, modular structures, or temporary builds, ground screw foundations offer a compelling economic advantage.

Before making a final choice, always consider the specific needs of your project site and long-term usage plans. But for many modern builds—ground screws are a smart, cost-effective alternative.

Xiamen TopFence Co.,Ltd.

Xiamen TopFence Co.,Ltd. No. 77, LingXia South Road, Huli District, Xiamen City, Fujian, China

No. 77, LingXia South Road, Huli District, Xiamen City, Fujian, China Điện thoại: +8613365923720

Điện thoại: +8613365923720

E-mail: info@xmtopfence.com

E-mail: info@xmtopfence.com

IPv6 mạng được hỗ trợ Sơ đồ trang web

| XML

| Blog

| Chính sách bảo mật

IPv6 mạng được hỗ trợ Sơ đồ trang web

| XML

| Blog

| Chính sách bảo mật